- Services

- Our services

-

Drug Substance

Process development, analytical development, analysis, stability testing, manufacturing

-

Solid State Research

Crystal structure by X-ray, solid form screening, solid form selection, IP support

-

Drug Product

Formulation development, analytical development, manufacturing, stability studies

-

Clinical Supply

Packaging, labeling, clinical trial logistics

-

Bioanalysis

Mass spectrometry, immunochemistry, flow cytometry, in-vitro drug discovery, clinical trial services

-

CMC Regulatory Support

Scientific report writing, module 3 writing, regulatory CMC support

-

- Advanced solutions

-

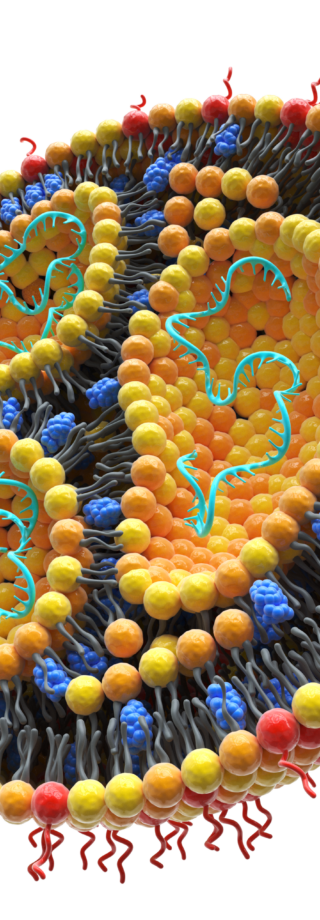

Nanomedicines

Guiding your nanomedicine candidate through its journey to the clinic

-

Bioavailability Enhancement

Developing and manufacturing formulations that lead to improved bioavailability

-

High Potency & Controlled Substances

Meeting your needs from pre-clinical to small-scale commercial manufacturing

-

Oral Drugs

Bringing your oral drug to clinical trials quickly and reliably

-

Injectable Drugs

Guiding you through the development of injectable drug products to GMP standards

-

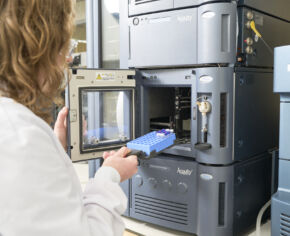

Preparative HPLC Purification

Enhancing biomolecule purity with tailored solutions for GMP-grade materials at scale

-

- Our services

- Integrated Platforms

-

Our integrated platforms

Program management

Using the right standards at the right development phase, our comprehensive program management services streamline your small molecule drug development.

Drug substance

Helping you turn your compounds that show promise into GMP-grade drug substances.

Drug product

We advance your clinical candidates through the pipeline quickly and safely with specialist drug product services.

Bioanalysis

Our bioanalytical platform supports your preclinical and clinical stages with expert testing services.

CMC regulatory services

Our comprehensive CMC regulatory services streamline preparation and submission of your registration file.

Program management

Using the right standards at the right development phase, our comprehensive program management services streamline your large molecule drug development.

Drug product

We advance your large molecule candidates through the pipeline quickly and safely with specialist drug product services.

Bioanalysis

Our bioanalytical platform supports your large molecule drugs through preclinical and clinical stages with expert testing services.

CMC regulatory services

Our comprehensive CMC regulatory services streamline the preparation and submission of the regulatory files for your large molecule drug.

Program management

Using the right standards at the right development phase, our comprehensive program management services streamline your nanomedicine drug development.

Drug product

We turn your nanomedicine candidates into suitable drugs with specialist development and manufacturing services.

Bioanalysis

Our bioanalytical platform supports your preclinical and clinical stages with expert testing services.

CMC regulatory services

Our comprehensive CMC regulatory services streamline the preparation and submission of the regulatory files for your nanomedicines.

-

- Resources

- About us

- About us

-

Mission and Vision

Always agile, we reliably guide you and your molecule through the challenging terrain of early phase development

-

Facilities

Carefully engineered to support and enable early phase development for our partners’ oral drugs, injectables and nanomedicines

-

Leadership team

Our leadership team has a deep scientific understanding combined with exceptional experience

-

History

Platforms and facilities that are uniquely engineered to support and enable integrated early phase development

-

Working at Ardena

We’re a fast-growing EU-based company with many opportunities for you to grow and progress with us

-

- About us

- Contact

News: Ardena's Nanomedicines Facility Receives First GMP Approval

Our newly expanded facility, featuring cutting-edge cleanrooms and laboratories, has been granted GMP approval by the Dutch Healthcare Authority. This €20 million investment underscores our dedication to innovation and excellence as a leading CDMO for nanomedicines.